A Piece of History

Little did I know that, in 1958 at the tender age of 18, I would become a part, albeit a very small part, of computing history in Canada when I was hired as an electronics technician to maintain Canada’s first commercially available electronic computer that had been relocated from the University of Toronto in Toronto to the National Research Council (NRC) in Ottawa.

My name is Brian Jeffrey although at the time of these events I was still using my adopted surname, Simon. Until June 2019, I believed that I was the last living person to have worked on Ferut. At that time I received an email from Martin Taylor who assured me that he had also worked on Ferut and was very much alive. Then in November of 2019, Martin Taylor uncovered the fact that Donald McQuirk (see below) was still above ground. We all share the dubious distinction of being the last three-four living people to have worked on Canada’s very first commercial stored-program digital computer.

This is my story. Martin and Donald will have their own.

My Story

The job at NRC was my second job since graduating as an electronics technician from the Ottawa Technical High School in 1957. In those years you could actually graduate from high school with usable skills.

My first job was as an assembly line worker and finally as a one-person assembly line doing the repair and overhaul (R&O) work on a piece of military test equipment known as the AN/ARM-1. I was paid the princely sum of $1/hour.

As a young lad I was not only technically competent and curious, I was nerd-like.

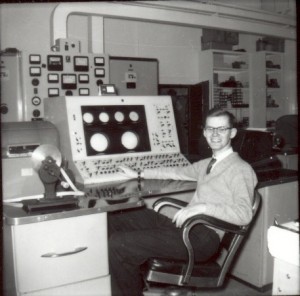

When the opportunity to move to the National Research Council (NRC) for $1.37/hour came up, I grabbed it. I vaguely remember being shown the computer as part of the hiring interview but I don’t remember being asked any questions about my knowledge of computers but then there were only a small handful of computers in the world at that time. I’m not sure what they saw in me apart from looking like a nerd (see picture) and having my Amateur radio (ham) license (VE3EBF). In those days, having your “ham” license usually meant that you were technically competent and curious, and I was both. So, in early 1958, I joined the NRC Structures Laboratory on Montreal Road in Ottawa and the adventure began.

Learning the Ropes

I was tutored by a Ferranti engineer by the name of Donald McQuirk (who, being British was indeed a bit quirky). Donald had been responsible for the decommissioning and moving of the computer from the University of Toronto to its new home in the back corner of M-14, the Structures Lab.

When I started there, Ferut’s installation was complete and final testing was going on. I followed Donald (not Don) around like a puppy on a leash trying to absorb as much knowledge as I could before he returned to England.

I could somewhat understand and read the schematics but the logic diagrams were like a foreign language to me. Like most people in the world at that time, I had no idea about the digital world and Boolean logic wasn’t something that I had learned at school. I quickly learned to keep my eyes and ears open and my mouth shut except to ask questions or seek clarification. I was a willing and eager student but Donald wasn’t the most patient of tutors and frequently displayed his frustration at my lack of experience. I also think that it annoyed him that I was a lowly electronics technician and not an electrical engineer.

Powering the Beast

Ferut did not take its primary power from the normal hydro power lines but had a pair of separate motor-generators (MG sets) that were located on the other side of the building in a separate room off the Machine Shop. I’m not sure if there was a technical reason for having them remote from the main system.

The generators and their respective motors were separate and connected by a coupling unit. I remember this quite well because one of the couplers broke and had to be replaced.

Donald was still coaching me at this point. He had tried to switch on the power but we were unable to get any DC. He sent me over to the MG room to report on what was (or wasn’t) happening when he tried to apply power. Standing overly close to any machine that is moving at high speed is not my idea of fun and I was very nervous. Whenever Donald tried to switch on the power the motor would scream and almost sent me into a panic. I erroneously reported to Donald that whenever he switched on the power the generator sped up. Of course, the opposite was happening, it was slowing down. He finally came over and had me go back to the main computer room and do the power switching. He took great delight in pointing out the broken coupler and the fact to I apparently had all the technical competency of a small pebble. Lesson learned.

One note of interest is that the power for the tube filaments came from their own MG set that ran at 1400 cycles rather than the usual 60 cycles. This meant that the filament transformers could be of a much smaller size as well as produce less heat. The other MG set provided all the remaining DC voltages for the computer.

On my Own

The day finally came when the brain bucket was full, there was no more to teach me, and Donald packed up and returned to Britain (or at least I thought that’s where he went at that time). I was on my own but being young and dumb, I was fearless.

Ferut wasn’t the most reliable of computers. In fact, by today’s standards it was an operational disaster. If I could keep it running for more than three hours at a stretch, I celebrated. Just powering the computer up was a production on its own.

With over 3600 vacuum tubes (the British called them “valves”) one or more were sure to die during the start-up process. I would slowly raise the filament voltage up over a three minute period in the hopes that the thermal shock wouldn’t destroy a tube filament somewhere. This technique rarely worked so I relied on my innate ingenuity by getting in to work early, turning the beast on and then going for breakfast in the NRC cafeteria. By the time I returned, Ferut was toasty warm and I could proceed with my maintenance routines that would usually isolate the problem to a particular section. I would then go to that section and feel each of the 50 or so tubes until I found the cool one which I then replaced. Not a particularly sophisticated trouble-shooting technique but it worked.

On a good day I might only have 2-3 tubes go south (die) upon start-up. On a REAL good day, I may only have one go bad. I rarely had good or real good days. It was not unusual for me to spend 2-3 hours getting Ferut to the point where I could turn it over to the scientists, much to our mutual frustration.

I had no benchmark as to my technical competency. Nor, fortunately for me, did anyone else, but in the land of the blind, the one-eyed man is king and I was the king of Ferut-land. I was somewhat disheartened with my seeming inability to keep Ferut running for any extended period of time, not realizing that I was probably doing extremely well for the times. To say that computers were unreliable was an astounding understatement. Back then, keeping them running for a few hours was a major achievement as I now know.

I only recently discovered that the University had a team of eight engineers who did about six hours a day of scheduled maintenance on the computer. I’m glad I didn’t know that back then. Ignorance is bliss!

Adventures in Air Conditioning

Air conditioning was relatively rare back then but because Ferut had over 3600 heat generating tubes, there was a 12 ton air-conditioning unit to keep it from burning itself out. As a consequence, the computer room was a mecca on hot summer days when people would drop in to see how things were going even though it was none of their business. There were some unintended consequences as well.

One Friday evening I was anxious to get home and I shut down Ferut but neglected to turn off the air conditioning unit. I knew that the scientists needed the computer early Monday morning so I decided to go into work on the Sunday to prep it. Much to my horror I found that the entire machine had frosted over. The computer room felt like a meat locker. Everything had a thin layer of frost and I knew if it thawed out fast that I’d have water dripping on sensitive electronic components.

Fortunately the frost seemed to be limited to the outside of the machine so I removed all the doors and put them outside in the sun to dry. It was a hot summer day so the room came up to temperature quite quickly and I was able to find a pile of rags with which to wipe up the small pools of water that had formed here and there.

I was smart enough to know that applying filament voltage to overly cool tubes was a recipe for disaster, or at least a lot of dead tubes, so I waited a few hours while things returned to room temperature and while room itself returned to room temperature.

By mid-afternoon I was ready to apply power and assess the damage. As luck would have it, I was having a good day and only a few tubes went south (died). By now all the doors had dried out so I replaced them and continued on with my maintenance routines in preparation for Monday.

When it was all over, I realized what I dumb thing I’d done by forgetting to turn off the air conditioning unit. I never told anyone about this adventure, electing to keep my dumbness to myself, until now.

Booting Ferut

I wasn’t a programmer nor did I know how to program Ferut. What I did know was how to enter in 8-10 machine language instructions from the console keys that would get Ferut to read additional instructions from a Creed paper tape reader. Talk about booting up a computer!

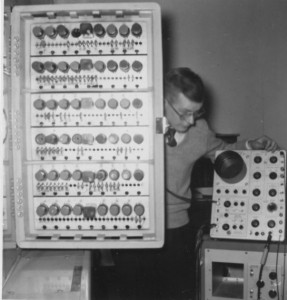

Once I had booted Ferut up I had a number of maintenance routines on paper tape that I would feed in via the Creed tape reader and read the results of the tests on the console CRT’s. Once I located the section of the machine that wasn’t working I started with more traditional trouble shooting techniques using an oscilloscope if necessary. Once again, feeling the metal EF-50’s or looking for filaments in the many thermionic glass diodes was my primary technique as probably 90-95% of the problems were dead tubes. The rest were adjustments of the Williams-Kilburn CRT storage devices or the magnetic drum memory.

Data Storage

The Williams-Kilburn CRT storage device was probably one of the earliest, if not the earliest, attempt at random access memory (RAM) although it wasn’t called that back then. In retrospect, the concept was fairly simple. There were 1024 dots on the CRT face. An unfocused dot was a “1” and a focused dot was a “0”. There was a metal face-plate in front of the screen and you measured the electrostatic charge between the CRT and the face-plate.

Clever as the concept was, they were pigs to keep adjusted. They seemed particularly sensitive to voltage variations as that would change the focusing of the dot. As I recall, we had eight and adjusting them would take between 10-20 minutes on a good day. You had to open the section, remove the metal plate in front of the CRT and adjust the relative difference between the focused and unfocused beams. Then you reassembled the face-plate and hoped that everything remained stable, which it rarely did so you’d repeat the procedure until it worked.

Because the electrostatic memory system was volatile, if you had a power failure or voltage surge, you’d often lose your data, and as the power was coming from Ferut’s own generators, voltage fluctuations were all too common.

Long-term permanent data was stored on a large rotating drum that was about 24 inches high, 18 inches in diameter and having 256 tracks of which 64 were available at any given time for a total of 650K worth of memory. When (not ‘if’) a track went bad, it would be replaced with one of the other available tracks. Once again, I developed a highly sophisticated method of adjusting the heads. I’d carefully screw the heads into the drums surface until I could hear the pinging of the head on the oxide and then I’d back it off by a half turn. Heh, it worked!

That’s my part of the story. The rest of this site is devoted to information on Ferut, the Ferranti Mark 1 computer, and other early computer trivia that I felt might be of interest. The Link page is a compendium of Internet sites pertaining to Ferut, the Ferranti Mark 1, and other relevant information such as programming, etc.

The Last Person Standing?

I used to think that I might be the last person standing to have worked on Canada’s first commercial computer but as noted at the top of this page, at least two more have appeared. If you wish to contact me to see if I’m still alive, I can be reached at BrianJeffrey@Xplornet.com.

And if you’d like to read about my post-Ferut “Adventures from the Coldest Part of the Cold War”, visit www.DEWLineAdventures.com.